Temperature is extremely important when choosing a bearing. Whether due to friction, electrical current, electromagnetic induction, or an extreme external environment, bearings are often required to perform in high temperature environments. We’ve provided this quick article to help you understand the essence of what it takes for your bearing to take the heat.

Bearings are very precise instruments, and for them to work properly, all their parts (races, rolling elements, cages) have to stay within tight engineering tolerances. For example, if the outer race were to expand too severely, the bearing could be in danger of wearing excessively, leaking lubricant, or otherwise stop performing properly.

As a second example, if one or more of the rolling elements were to deform, the bearing would no longer run smoothly, and may even jam up and fail catastrophically. Effects like these can be experienced in high temperature environments, when the expansion is significant.

Bearings have a finite design lifetime, as over time the steel will expand, deform or wear, impacting the bearing’s tolerances and clearances. Aging effects are normally slow and gradual; however, extreme temperatures can dramatically accelerate the bearing aging process.

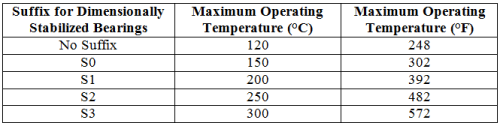

At Action Bearing we address this issue by guaranteeing all of our bearings to be dimensionally stable within certain operating temperatures. This means that as long as a bearing is not used above the maximum operating temperature, its critical dimensions will remain within specified tolerances for the bearing lifetime.

In a nutshell, your bearing will continue to perform as your design requires. However at temperatures outside the guaranteed operating range, bearing life and performance should be expected to decrease according to the loading conditions and the operating environment.

The table below lists our dimensionally stabilized categories divided by maximum operating temperature:

No matter what your application, we are here to help. Action Bearing has years of experience providing high quality bearings to many different industries, and our technical team is here to help you choose the right bearing for your application. If you need to know if your bearing can take the heat, contact us today or visit our Catalog and Technical Toolbox webpages. These resources include information intended to help accelerate your decision-making process.

Please visit Emersonbearing.com for our latest blogs and updates!

Please visit Emersonbearing.com for our latest blogs and updates!